MANGO LLIÇÀ D’AMUNT

Innovation and Efficiency: The New State-of-the-art Machinery at MANGO’s Facilities in Lliçà d’amunt.

In a constantly evolving business world, the ability to adapt and the search for excellence are key to success. In this context, MANGO, the renowned international fashion brand, has taken a step forward by inaugurating its new facilities in Lliçà d’Amunt, which not only mark a milestone in terms of infrastructure, but also usher in a new era of innovation and efficiency in the textile industry. One of the cornerstones of this cutting-edge project is the implementation of state-of-the-art machinery, designed to optimize production processes and enhance product quality. With a focus on automation and digitalization, MANGO has made a strategic investment to ensure that its operations are at the cutting edge of technology. This article aims to explore in detail the crucial role played by TAIMU’s new machinery at MANGO’s Lliçà d’Amunt facility. From its design to its implementation and the benefits it brings, we will examine how this investment is transforming the way MANGO approaches production and positions itself as a leading company in the fashion sector.

CHALLENGE

Description

MANGO’s new facilities in Lliçà stand out for their leadership in the automation of the picking process. In these facilities, a variety of products are stored in a high-capacity rack and are automatically selected for inclusion in boxes of different volumes, in accordance with the quantities required for each destination point. Subsequently, after the products have been properly packed, each box is directed to a specific position on a shuttle, following label identification and in consideration of the method of transportation for which they are destined.

However, the distribution system for these boxes, known as a “sorter,” sometimes experiences challenges in processing label information, either due to misplaced or missing labels. In these situations, the boxes in question are redirected to an area called “manual re-entry”. This is where boxes of different sizes are brought together.

It is at this stage that the need arises to develop and implement a case coding system capable of adapting to variations in the height of each case before they return to the sorter, which will position them according to their final destination. This challenging automation project is carried out in collaboration with UBS (United Barcode Systems), whose high-capacity MRX head will be responsible for carrying out the coding on each of the boxes in order to maintain a good marking cadence and avoid the use of labeling paper, and VANDERLANDE, the expert in transport systems and warehouse logistics, which is responsible for weighing, validating measurements and reading the barcode on each box, as well as transporting them along the manual re-entry system.

Main requirements

Once the field of application and the customer’s needs have been established, the requirements that the coding system to be designed should meet are detailed:

- Adaptability to different case sizes.

- The print head must be positioned 1mm from the surface of the box to ensure good coding.

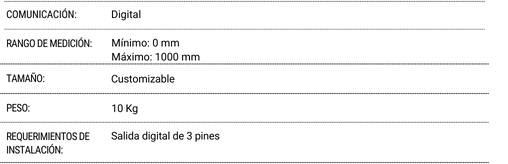

- The measuring system must have a resolution greater than 1mm.

- Conectivity with the Vanderlande system and the UBS printer.

- The maximum coding rate should be one box every 3s on a 900mm strech.

Handicaps

Due to the fact that we work with boxes of different sizes and that they do not always carry the same amount of products inside, a number of handicaps arise:

- Irregularity of the boxes on the top face, where the taping is done and some may arrive pumped.

- Blows at the boxes to the height meter because of their speed..

Characteristics of the boxes

The boxes can have a measurement range of::

- Length 230-800

- Width 210-600

- Haight 80-400

Taking into account that they will be justified on one side, se only depend on varying the height.

DESCRIPTION OF THE SOLUTION

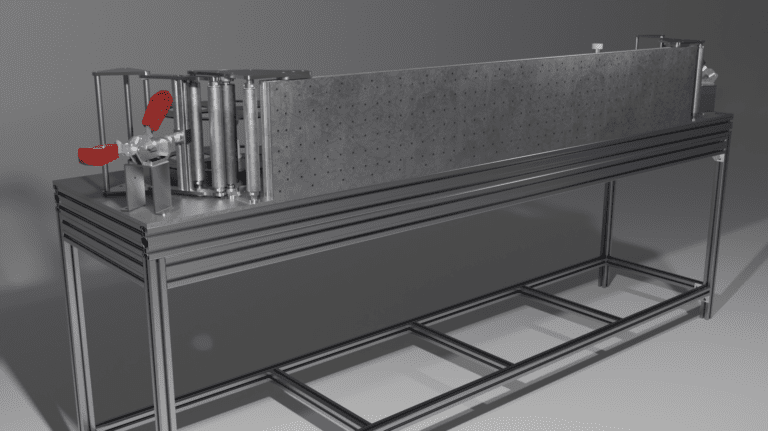

Once the requirements were defined and the main operational conflicts that could arise were detected, the BCNC team (acronym of the company or project) opted for the implementation of two autonomous systems that would operate in a collaborative manner: a fully mechanical high performance measuring system, called “PULSAR”, and a high load vertical lift, referred to as “DLV”. These systems are designed to work in synergy with the personnel present in their environment and, at the same time, significantly improve operational efficiency in the manual re-entry zone.

The main features of these systems include:

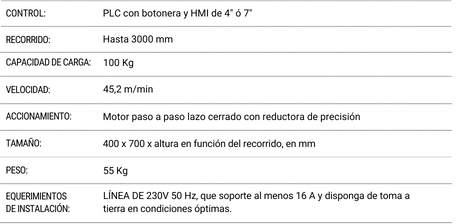

- DLV. The DLV is a high-precision vertical lifting system. Its main function is to lift heavy weight components with extremely precise accuracy and repeatability, reaching a tolerance close to one millimeter. This high level of precision is achieved thanks to an integrated system that includes a precision pulley, a high-precision gearbox and a high-resolution servomotor.

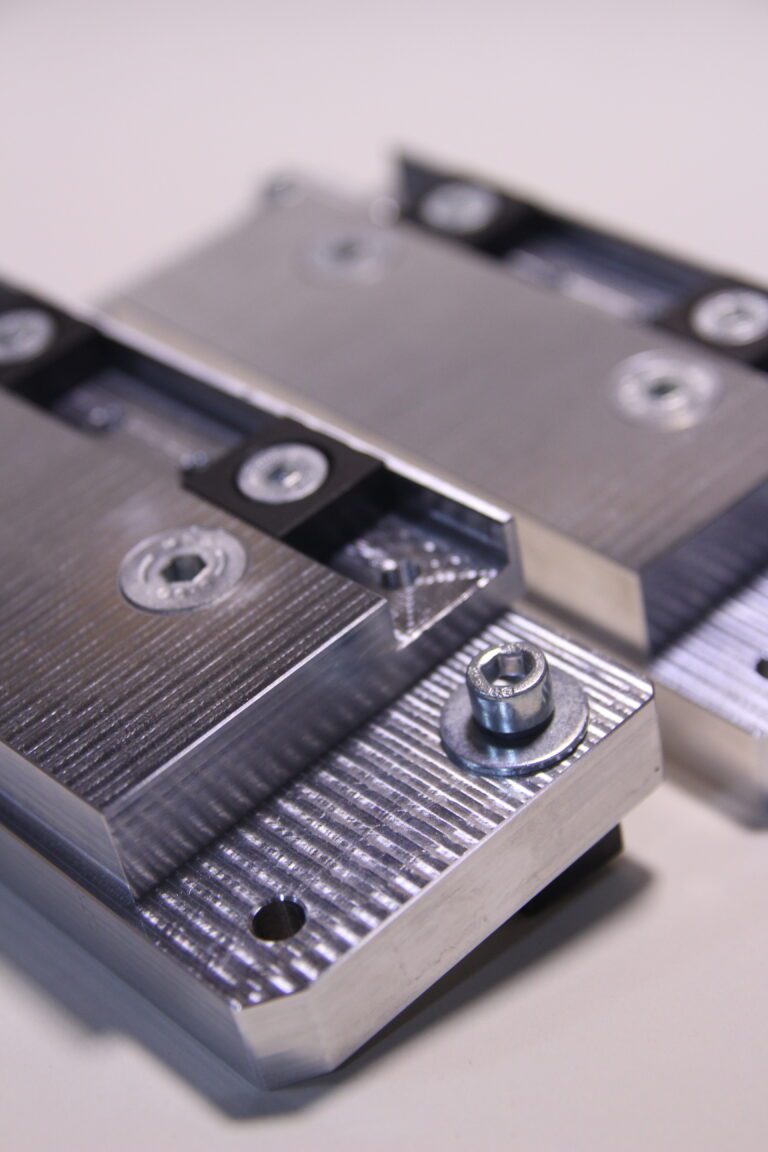

- Mechanical measuring system (PULSAR). The pendulum-type mechanical measuring system is a device designed to improve accuracy in case measurement. Its distinguishing feature is a skate-type arm equipped with wheels, which allows continuous and smooth contact with the surface of the box being measured. This results in high measurement resolution, making it possible to obtain accurate data on the length of the box. The main key features incorporated in the system are; a high resolution encoder, which thoroughly records any displacement, allowing fine resolution in the data collected and a damping system, which prevents the arm from hitting the chassis with force when stopping to measure a box, which could result in inaccurate readings or damage to the device.

The layout diagram of the assembly would be as follows:

PROCESS

The boxes, once weighed on a pre-weighing belt controlled by VANDERLANDE, (instant where the network identifies the product and knows the information to be printed on the box) pass through the measuring arch where the PULSAR system is located and is responsible for determining the height of the box.

All this information is transmitted to the DLV system, which requests the maximum height data recorded for positioning, and the MRX printer, which receives the information to be printed.

Through different encoders arranged along the conveyor belt, we know the exact position of the box during the whole process. Once the system is sure that the box has left the printing area, the next one enters.

RESULTS

The manual re-entry process of boxes with products is a crucial stage in MANGO’s supply chain, where the correct identification and labeling of the boxes are fundamental to guarantee efficiency and precision in the shipping process. In order to improve this process and reduce the manual workload, this intelligent and versatile industrial machine has been designed.

The main objective of this project has been to implement an automated solution that can dynamically adapt to different case heights, ensuring accurate printing of relevant coding such as lot numbers, expiration dates, product information and destination labels. This adaptability will ensure that each case is labeled correctly, regardless of its size or contents, reducing errors and minimizing time spent on manual adjustments.

This initiative proves to be an effective solution to increase productivity and accuracy in MANGO’s packaging process, allowing for a more efficient workflow and improved satisfaction. With this machine, MANGO will be one step closer to achieving its goals of operational excellence and service quality in its supply chain.

We would like to thank all the departments and teams involved in this project, as their commitment and cooperation are vital to the overall success of the initiative, especially our partner UBS, for trusting us again for such an exciting and beautiful project for engineering lovers like us.

El equipo de TAIMU.